Organic Waste to Clean Energy

Our Biogas Series stands out for its ability to transform organic waste into renewable energy. With a firm dedication to sustainable energy practices, our advanced microbial formulations are specifically engineered to optimize the process of biogas production. We are turning waste management into a powerful source of energy for a greener tomorrow.

Waste to clean energy processes generate renewable energy, which helps diversify the energy supply and mitigate climate change. Our products empower clients to improve waste management and increase biogas production, a financially viable alternative to traditional waste disposal and reliable and efficient energy generation.

By choosing the Biogas Series, you're not only investing in advanced technology but also contributing to a more sustainable and environmentally friendly future. Join us in our mission to turn waste into a valuable resource and power a greener world.

Struggling with Digester Performance?

We help anaerobic digestion operations around the world overcome challenges like solids buildup, low methane concentration, and high H₂S — with targeted biological solutions that are proven to work.

PRODUCT LINE

The process to convert organic waste into biogas is called anaerobic digestion and it involves four key stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Our Biogas Series products are meticulously crafted to enhance each phase of this process, ensuring optimal performance and efficiency.

-

Read More

Read MoreBGE1 is a high-performance microbial blend designed for the effective decomposition of diverse organic compounds. This product leverages a variety of bacteria, including aerobic, facultative anaerobic, anaerobic, photosynthetic, and chemosynthetic types, setting the standard for waste management and environmental care.

-

Read More

Read MoreBGE2 is a game changer in organic waste degradation. It combines humates, humic substances, and beneficial bacteria to stimulate enhanced microbial oxidation. This powerful fusion leads to a substantial increase in biomass activity, accelerating the breakdown of slow-to-degrade organic waste.

-

Read More

Read MoreBGEM features a unique blend of acetolactic methanogens and hydrogen-oxidizing methanogens, optimized for converting acetate and methyl groups into methane. This product significantly boosts methane concentration and biomethane output.

-

Read More

Read MoreBGEH is an advanced enzyme blend

including cellulase, hemicellulase, and micronutrients designed to improve the hydrolysis of lignocellulosic materials. This process enhances the microbial enzymatic solubility of such materials, leading to increased methane and biogas yields.

Available Sizes:

|

|

|

| 5 gal (18.93 L) | 55 gal (208.2 L) | 275 gal (1041 L) |

Application Rates:

Simple Application, Significant Results - Our application rates are designed for ease of use and maximum impact. Simply follow our directions to achieve optimal results:

For BGE1 and BGE2: Apply at a 50:50 ratio directly into the feed tank at 1 gallon of combined product per 100,000 gallons of reactor capacity per day.

Available Sizes:

|

|

|

| 5 gal (18.93 L) | 55 gal (208.2 L) | 275 gal (1041 L) |

Application Rates:

Simple Application, Significant Results - Our application rates are designed for ease of use and maximum impact. Simply follow our directions to achieve optimal results:

For BGE1 and BGE2: Apply at a 50:50 ratio directly into the feed tank at 1 gallon of combined product per 100,000 gallons of reactor capacity per day.

Available Sizes:

|

|

| 4.5 gal (17 L) | 50 gal (189.3 L) |

Application Rates:

Simple Application, Significant Results - Our application rates are designed for ease of use and maximum impact. Simply follow our directions to achieve optimal results:

For BGEM: Apply one gallon of BGEM for every 100,000 gallons of reactor capacity directly into the feed tank once every week.

Available Sizes:

|

| 10 Kg. |

Application Rates:

Simple Application, Significant Results - Our application rates are designed for ease of use and maximum impact. Simply follow our directions to achieve optimal results:

For BGEH: Apply one pound of enzymes for every 1 million gallons of digester capacity per day. Mix product with non-chlorinated water and apply directly into the feed tank for best results.

Become a Strategic Partner or Distributor

Join our global network of partners turning waste into renewable energy. Whether you want to expand into the waste-to-energy sector or add proven microbial solutions to your portfolio, we’ll help you succeed. We provide sales tools, technical training, and performance-backed products to support your growth.

Product Recommendation Chart

| Feedstock for Anaerobic Digestion / Problem | Product Recommendations | ||||

| Category | Composition/Reason | BGE1 | BGE2 | BGEH | BGEM |

| Cow Manure/ Bedding | Organic with High Cellulose/Hemicellulose |  |

|

|

|

| Hog or Poultry Manure/ Bedding | Organics |  |

|

||

| Wastewater Solid /Sewage Sludge | Organics |  |

|

||

| Agricultural Biomass/Crops/Grass | High Cellulose and Hemicellulose/Organics |  |

|

|

|

| Food Waste | Organics with High Fats/ Oils/ Grease |  |

|

|

|

| High FOS/TAC ratio | High Total Volatile Acid |  |

|||

| High H2S | Hydrogen Sulfide Generation |  |

|||

| Solid Accumulation/Foam | Difficult Degradable Sludge |  |

|

|

|

| Gas Product Inconsistency | Less Diverse Methanogens |  |

|||

| AD Startup | Requiring hydrolysis bacterial and methanogens |  |

|

||

REAL WORLD RESULTS

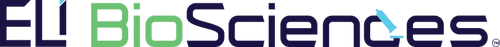

Desulfurization Case in Northern Ireland

A digester operator in Northern Ireland encountered issues with high hydrogen sulfide (H2O) levels of 270 ppm and decreased methane (CH4) production. To tackle this problem, they treated their 600,000-gallon anaerobic digester, processing a mixture of grass, chicken litter, and manure slurry, with daily doses of BGE1 and BGE2, obtaining a 30% reduction of H2S and a 5% increase in CH4 content which translates into 9% more biogas yield.

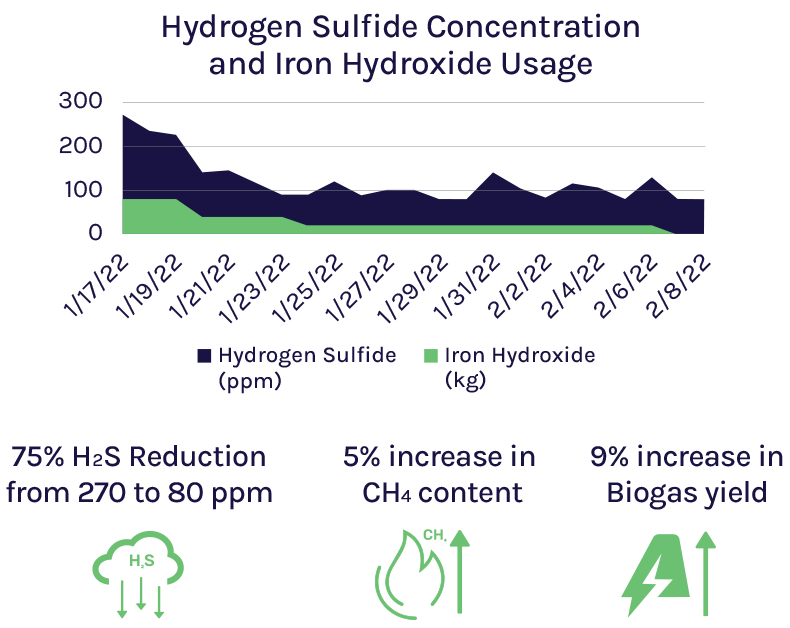

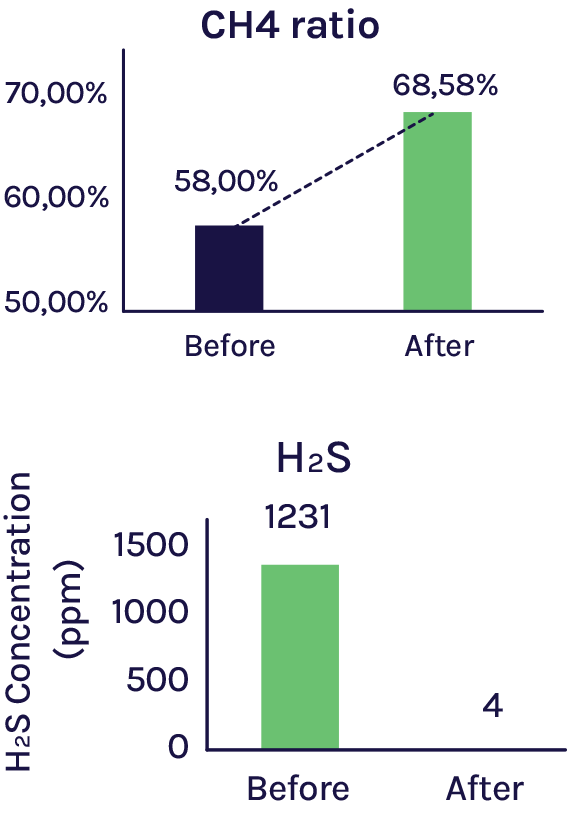

Kurtz Family Farm - Biogas Series Brings Inoperable Digestor Back to Life

The Holstein Family Farm in Pennsylvania, operating two 150,000-gallon anaerobic digesters, were facing severe concerns with their reactors. The combined feed stock of poultry waste and dairy manure are very high in FOGs (fat, oil and grease), protein, and chemical constituents. Difficulty breaking down these organisms resulted in bulking, low methane output, and very high hydrogen sulfide levels.

Following treatment with Eli Biosciences, the reactor’s performance shifted dramatically. The methane percentage grew by 10%, solids were completely eliminated from the balancing tank, and hydrogen sulfide levels were undetectable.

Protect Your Equipment. Boost Your Output.

Your digester is a major investment, keep it running at its best. Our microbial blends help reduce H₂S, prevent corrosion, and stabilize methane production without adding complexity to your process.

RETURN ON INVESTMENT (ROI)

The benefits of the Biogas Series extend far beyond enhanced biogas production, delivering a tangible return on investment. Here's how our cutting-edge solutions transform your waste management and biogas production:

-

Boost Biogas Output: Increase your biogas output by up to 25%. This significant boost in output directly translates into higher energy generation and greater profitability.

-

Lower Hydrogen Sulfide Levels: Benefit from a biological reduction in hydrogen sulfide by up to 75%. This improvement not only enhances safety but also reduces startup time for new reactors, allowing for quicker and more efficient operations.

-

Reduce Input Costs: Slash your input costs by an impressive 50%. Our Biogas Series is designed to maximize efficiency, ensuring you get more for less.

-

Eliminate Reactor Bottom Solids: Our Biogas Series eliminates solids and sludge, enhancing reactor capacity by up to 10%. This means fewer interruptions and more consistent, reliable biogas production.

-

Enhance CH4 Methane Concentration: Achieve up to a 7% increase in methane concentration. Higher methane levels mean optimal energy yield, enhancing the overall

efficiency and effectiveness of your biogas system. -

Sustainable and Profitable: Discover a perfect blend of efficiency, sustainability, and profitability. Our innovative solutions ensure you achieve your sustainability goals while also maximizing your return on investment.

Unlock the full potential of your biogas production with the Biogas Series and experience the tangible benefits of advanced waste management technology.

Producing biogas from organic waste offers numerous environmental advantages. It significantly reduces the volume of waste sent to landfills, decreasing the release of harmful methane emissions. By converting waste into energy, we also reduce the reliance on fossil fuels, cutting down greenhouse gas emissions and promoting cleaner air. Additionally, biogas production helps in recycling nutrients back into the soil, improving soil health and agricultural productivity.

Get in Touch

Whether you’re operating a digester, looking to improve performance, or interested in becoming a partner/distributor, this form is the place to start.

Share the basics with us, and we’ll get back to you with the right next step.